The riveting is carried out in the hole corresponding to the two parts and the rivet gun is used to pull the rivet to expand.

A small rivet connecting two pieces of sheet metal.

Works well in tight areas or where space is a premium.

Popular in electronics applications.

The allowance is normally about 1 5d.

With all mentioned parameters you can calculate the desired length of the rivet.

This video shows how to install rivets as per hb39.

Keep in mind that pop rivets are not a permanent solution but they will keep the metal in place long.

Determine the impulse exerted on the rivet and the energy absorbed by the rivet under each blow knowing that the head of the hammer has a weight of 1 5 lb and that it strikes the rivet with a velocity of 20 ft s.

They re usually made of soft iron or steel and have a flat head.

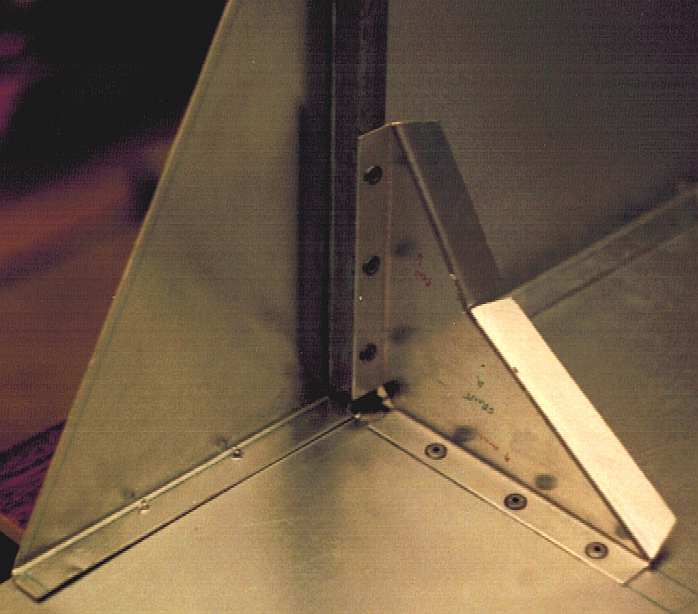

The two pieces of sheet metal connected to each other by folding or bending tabs in the form of a buckle and a clamping slot.

I have done quite a lot of riveting in my life and i must say besides welding it is my favorite method to join sheet metal together.

However for sheet metal you can easily buy some small rivets as well as rivet pliers from amazon.

Like with riveting you just need two pieces.

Ideal for thin sheet metal and printed circuit boards.

Problem 152p from chapter 13.

The proper diameter rivet would be 3 x 0 050 0 150 inch 3 x 1 27 3 81 mm.

A small rivet connecting two pieces of sheet metal is beingclinched by hammmering.

Used for thin sheet metal tinner s rivets are solid rivets.

Determine the impulse exerted on the rivetand the energy absorbed by the rivet under each blow knowing thatthe head of the hammer has a mass of750g and that it strikes therivet with a velocity of 6m s.

For example two pieces of 0 050 inch 1 27 mm sheet are to be riveted together.

A 5 32 rivet 0 156 inch 3 96 mm would be used.

Rivets are used to form solid strong and permanent bonds.

This application can be used for box gutters cappings flashings eves gutters etc.

A small rivet connecting two pieces of sheet metal is being clinched by hammering.

The original rivet head is called the factory head and the secondary head made after popping the rivet is called the shop head or the buck tail.

Blind hole one sided installation capability.

Very low secondary side.

A small rivet connecting two pieces of sheet metal is being.

This assembly method is relatively simple and convenient and can complete rapid assembly.